Printed Circuit Board (PCB) Fabrication

ISO 9001:2015 | AS9100 Rev. D Certified | IPC-A-610 CLASS 1-2-3 | J Std 001E Class I, II, and III

Our expertise spans over various facets of printed circuit board fabrication, making us a leading PCB fabrication company with capabilities tailored to meet diverse industry needs. At TechnoTronix, we excel in both Surface Mount Technology (SMT) and Through-hole assembly processes, ensuring versatility in component placement for all types of PCBs. Our advanced equipment supports High-Speed Placement, enabling efficient assembly of complex boards with components such as Ball Grid Arrays (BGA) and Micro-BGA, including fine pitch components like 01005 and 0201 sizes.

We offer comprehensive services that cater to every stage of PCB fabrication and assembly. From optimized Reflow Profiling for precise soldering to handling Turnkey or Consigned Kits as per customer preference, we ensure flexibility and efficiency in our operations. Our capabilities extend to specialized services such as Press Fit Connector installation, accommodating prototype quantities with quick-turn capabilities (including Same Day & Next Day services), and managing scheduled deliveries for production quantities.

TechnoTronix is equipped for high-volume production demands, providing expertise in Double-Sided SMT assembly and ensuring quality through De-ionized Wash processes. Our capabilities include comprehensive rework services, de-population, re-population, and handling cuts & jumps for circuit modifications. We uphold strict ESD Control measures to maintain product integrity throughout fabrication and assembly.

Collaborating closely with our in-house layout team, we address Design for Manufacturing (DFM) and Design for Test (DFT) issues effectively. Additionally, our expertise extends to Mechanical Assembly and Box Builds, complemented by Cable & Harness Assembly services. Each project undergoes rigorous Functional Testing to verify operational performance and adherence to specifications.

As a trusted PCB fabrication company in the California USA, TechnoTronix combines advanced technology with extensive industry experience to deliver custom circuit board fabrication services that meet the highest standards of quality, reliability, and efficiency.

PCB Fabrication Services

Prototype PCB Fabrication

Quick-Turn PCB Fab

Flex PCB Fabrication

Rigid PCB Fabrication

Rigid-Flex PCB Fabrication

Multi-Layer PCB Fabrication

Metal Core PCB Fabrication

HDIs (High-Density Interconnects) PCB Fab

Low-Volume PCB Fab

High-Volume PCB Fab

Our PCB Fabrication Capabilities

| Capability | Standard |

|---|---|

| Shapes: | Circular, Rectangular, Custom |

| Circuit Board Base Materials: | RoHS compliant, RF and advanced RF, Aluminum clad |

| Boards Type: | Metalcore, Aluminum backed, Rigid, flex, etc., Multilayer PCB up to 24 Layers |

| Alternative Finishes: | Hot Air Solder Level, Electroless Nickel / Immersion Gold, Silver, Electroless Tin Lead, Organic (OSP), Hard Gold (edge contact), Carbon, Peelable |

| Designs: | Countersinks and bores, Controlled dielectric and impedance, Cover coat, Edge mill and Back drilling |

| Drill: | Small size, Large size, Control depth and positional tolerance |

| Circuit Boards Parameters: | Layer count and board thickness, Copper weight, |

| Printed Circuit Board Profiling: | CNC Rout, CNC Score, Pierce Blank & Return |

| Advanced Options: | Carbon mask, Golf fingers and edge plating, Kapton tape |

| Advance Designs: | Blind Vias, Buried Vias, Multilayer design, Stacked micro vias |

| Bare Board Test: | Bed of Nails, Simultaneous double-sided flying probe test |

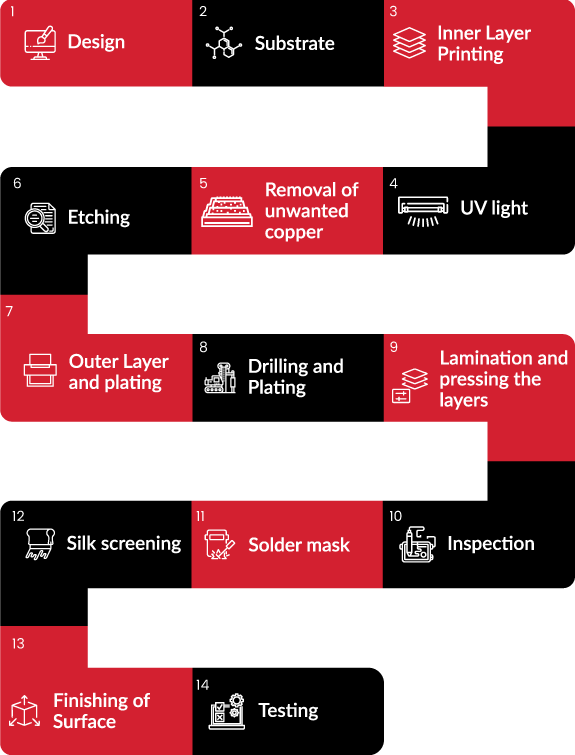

PCB Fabrication process and technology

The process of printed circuit board (PCB) fabrication is a meticulous journey from initial design to physical realization, essential for ensuring the integrity and functionality of electronic devices. TechnoTronix, a distinguished leader in PCB fabrication with extensive expertise, adheres to a meticulous process to transform circuit board designs into durable physical structures that consistently meet stringent specifications and industry standards.

The printed circuit board fabrication process commences with the design package, usually provided in Gerber file format, serving as the foundational blueprint for manufacturing.

Below is a comprehensive overview of the ensuing steps involved in this intricate process:

- Design Package Transformation: Circuit board designs are translated into physical structures based on precise specifications outlined in the design package.

- Image Transfer: Utilizing advanced techniques such as photo tooling and direct imaging, the circuit board designs are transferred onto the board's surface. Each layer undergoes laser printing individually to ensure accuracy and alignment.

- Multilayer Construction: Multilayer PCBs are composed of multiple layers of dielectric material and metal conductors. These layers must be meticulously controlled for copper weight, width, and alignment to achieve the desired final product.

- Inner Layer Circuit Imaging: Inner layer circuit images are created using photoresist exposure, either through UV light or direct laser imaging. Automated Optical Inspection (AOI) systems are employed to detect and rectify any defects in the core layers.

- Layer Bonding: Each layer pair is sandwiched with "prepreg" material to facilitate bonding during the lamination process. Proper alignment is crucial to ensure uniformity and integrity across all layers.

- Lamination Process: The layers are laminated together under heat and pressure, fusing them into a single, solid PCB structure.

- Drilling: Holes are drilled into the PCB for component mounting, through-hole vias, and non-plated holes for mechanical features. Special considerations are made for buried, blind vias, or microvias, which are fabricated prior to lamination.

- Solder Mask and Surface Finish: A solder mask is applied to protect the PCB surface, followed by surface finish applications to enhance durability and facilitate soldering during assembly.

- Final Testing: Before assembly, finalized PCBs undergo rigorous testing using techniques such as flying probe or bed of nails test fixtures. This ensures that each board meets quality standards and operational requirements.

TechnoTronix utilizes advanced equipment and a highly skilled workforce to meticulously execute every stage of the printed circuit board (PCB) fabrication process with precision and efficiency. As a dedicated PCB fabrication company, we prioritize excellence in quality assurance and customer satisfaction. Our commitment is reflected in our ability to provide customized circuit board fabrication services that cater to a wide range of industry needs. From prototype development to high-volume production, we serve clients across diverse sectors such as aerospace, medical devices, and telecommunications, among others.

For reliable PCB fabrication services in the California USA, trust TechnoTronix to deliver innovative solutions that meet your exact specifications. Contact us today to discuss your project requirements and discover how we can partner in bringing your PCB designs to life with expertise and reliability.

Why Choose Technotronix as PCB Fabrication Company?

- TechnoTronix boasts over 44 years of experience specializing in printed circuit board fabrication services.

- Our state-of-the-art manufacturing facility enables us to fabricate circuit boards, assemble components, and build prototypes efficiently.

- We offer in-house testing, ensuring cost-effective mass production of PCB fabrications.

- For standard projects, our lead time ranges from 1 to 5 days, while complex projects typically require 1 to 2 weeks. Urgent orders are accommodated promptly.

- We adhere to the ISO 9001:2015 quality management system, guaranteeing standardized and quality PCB fabrication services that meet the requirements of various industrial applications such as electronics, medical devices, and telecommunications.

- Whether you need low volume, prototype, or high-volume circuit board fabrications exceeding 10,000 pieces, we handle all project types.

- Leveraging our advanced printed circuit board fabrication capabilities and state-of-the-art technologies, we ensure timely delivery and meet customer specifications.

- We provide lead-free and RoHS compliant materials upon customer request, ensuring environmental compliance and safety.

- Our solutions are designed with industry standards and guidelines in mind, prioritizing security and safety concerns.

TechnoTronix is dedicated to delivering superior printed circuit board fabrication services, backed by decades of expertise and a commitment to quality and customer satisfaction.

PCB Fabrication Services for Various Industries

Our printed circuit board fabrication services cater to a wide range of industries, including but not limited to:

Industrial Automation and Control Systems

Robotics and Machinery

Sensing and Monitoring Systems

Power Distribution and Management

Instrumentation and Measurement Equipment

Process Control and Optimization

Industrial Networking and Communication

Safety and Security Systems

FAQs

Things to consider when choosing the right PCB fabrication service:

- Assess your requirements: Consider factors like board complexity, quantity, turnaround time, and budget.

- Research options: Look for reputable services with good reviews, certifications, and experience in your project's requirements.

- Evaluate capabilities: Check if the service offers the needed technology, materials, and additional services like assembly and testing.

- Cost comparison: Compare quotes from multiple services, considering quality, lead time, and additional charges.

- Communication and support: Choose a service with responsive customer support and clear communication channels for any queries or issues.

For more information check out

Our Most Recent and PCB Assembly Related Articles

Do you have any PCB Fabrication requirements? Request a free PCB Fabrication quote. Alternatively, email BoM, Gerber files, and other required details at [email protected] or call us 714/630-9200.

PCB Assembled in 24 hours

Kitted and Turn-Key option as per customers requirement.

REQUEST OUR BROCHURE

Request Brochure

Request Brochure Please provide your email address. We’ll send you copy of our brochure in a PDF format.