Simple Ways To Reduce PCB Assembly Cost

When it comes to high cost being a common crunch regardless of the improving economy, many of the American industries are tracking down the effective ways to scale back the costs and upgrade profit margins without compromising on quality aspects of product and process development especially in the electronic industry. One of the most trending issues experienced by electronic manufacturers and OEM is constantly changing technology with the need of more and more complex PCB assembly services. For all these issues, there is certainly a happy medium or a middle ground to be considered to reduce the cost of PCB assembly with maintaining the quality standards in every phase of the PCBA. So folks! Let’s rev up to further content that uncovers savvy ways for making the PCB more cost effective with smart steps to bringing modification to the assemblage of printed circuit boards.

It’s all about keeping it pretty simple, easy and as direct as possible to reduce the cost of PCBA instead of seen it as a complicated dance to make it more compact, multi feature and reliable. For most of the electronic manufacturers, searching for the zone that proves vital for safely minimizing the spending along with keeping the customers satisfied with the quality products isn’t easy. It’s difficult to balance the project schedule and budget at the same time. On the other hand is the strict inspection operation that drives an increase in cost which proves more expensive if ignored or not implemented during a PCB assembly. With this, why not gain more fortunes of cost savings by trying out some simple ways and method?

Top PCB Assembly Cost Breakdown ways

-

Minimize complexities

by coming up with many different design options that can help to plan out suitable prototype at a first go.

-

Shape it right

by applying a common structure to cut down on the cost. Complex shapes usually result in a cost rise.

-

Smart and Slick pcb layout

are at the rim of the basket. One of the significant stages in PCB assembly that steals the show along with a need of effective planning to curtail the cost is the pcb layout phase. The optimum use of required high quality parts and components that can promptly lower down on the cost per PCB is possible with strategical PCB engineering.

- Take sufficient time to come up with a complete and categorical Bills of Materials (BOM). An effective BOM should include all the essential elements like reference designator, part number, description, quality, SMT method, manufacturer name, footprints, package and BOM level. It is of utmost consideration to add the

element of Component Replacement in the BOM

as the technology develops faster and need the old elements to be immediately be replaced with the new ones to match up the competitive market trends.

-

Avoid extra cut outs in the boards

that can add on to the cost of PCBA that doesn’t make a vital difference on brand recognition or functionality.

- Go ahead with a

strict DFM check

to probe for a particular circuit is normally implemented that can taper off the cost of PCB assembly.

- Plug in to the chief factors considered or headway to perfection with effective optimization and revamp

the schematic layout of a bare PCB.

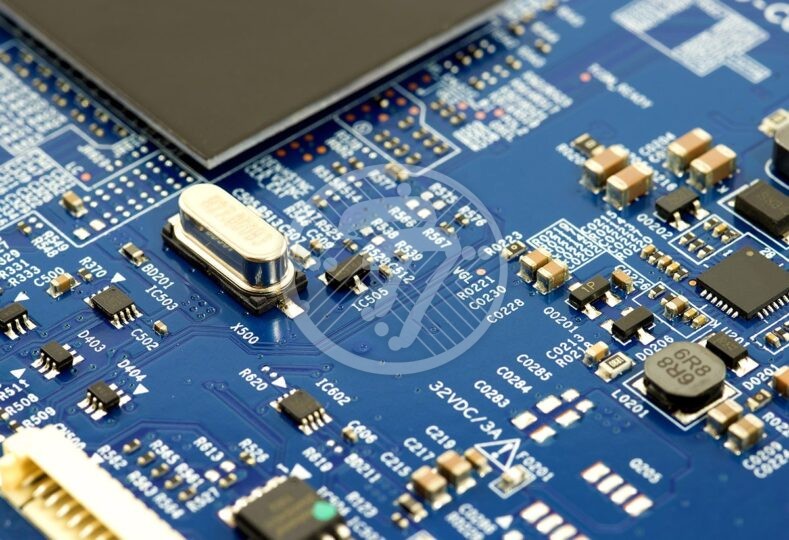

Simply get a basic idea of the factors presented in the following diagram: (Insert the image)

- Work out a good deal with a

fine balance of order value.

More the order, lesser the price of each PCB assembly.

-

Adjust the lead time

after knowing the way your PCB assembler calculates the lead time. Clear all your doubts pertaining to the initiation of the start time, day of order, day of payment, date of receiving the components, etc.

-

To

consciously choose a professional expert

and reliable PCB manufacturer/ PCB assembler. The majority of the PCB assembler declares to offer cost effective PCB assembly services. But many customers don’t get satisfaction since they do not receive what is being claimed.

To avoid these kinds of vital issues, Let’s take a jaunt to factors that will help to choose your PCB manufacturer very consciously:

-

Look for the Certifications

that assure a good manufacturing capability and quality management system of a PCB assembly service. RoHS compliance, ISO9001, UL and many more are the international quality management standards that have now become mandatory to improvise the quality of process and products.

-

High-tech equipments,

well defined tool room and implementation of upgraded technology contributes to receiving quick turnarounds along with high efficiency, required manufacturing speed, high precision placing and effective inspection. In the present world of innovation, with the adoption of Surface Mount Technology, Through Hole Technique and other specialized PCB technology, these factors need to be of prime priority in the checklist.

-

Component procurement

is also one of the chief considerations for selecting a suitable PCB manufacturer. Apart from focusing on the PCB engineering and PCB fabrication mechanism, it is of great concern to verify the component sourcing capabilities, vendor management and supply chain network that are competitive at large.

At Technotronix, we are fully equipped to handle your PCB manufacturing requirements. With over 4 decades of experience in PCB manufacturing as well as assembling PCBs with differing levels of complexities, we follow industry best practices to ensure we deliver cutting-edge products. Our team of experts and state-of-the-art equipment ensures that all our PCBs meet the industry standards of quality and testing. It is our vast portfolio of satisfied clients that stand as the biggest testimony to our success. In case if you have any questions, please feel free to contact us via email at [email protected]