ATE PCB Assembly – The trusted interface between PCB manufacturer and OEM

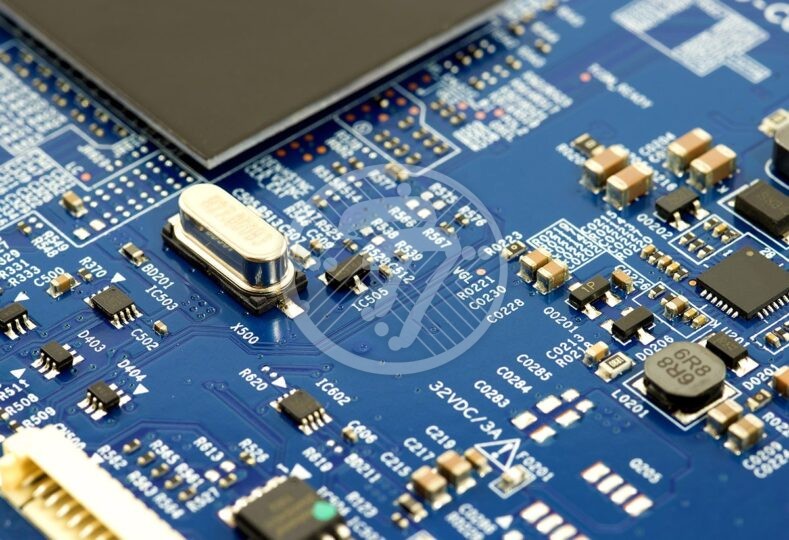

ATE (or an automatic test equipment) PCB is an important interface when it comes to verifying a semiconductor chip’s functionality. With semiconductor chip technology having become extremely advanced, testing the devices is a must do in order to verify its functionality and reliability. For the same reason it has evolved as a trusted interface between PCB manufacturers and their OEMs as it helps manufacturers to demonstrate the reliability of their products and for OEMs to believe in it.

ATE PCBs can test a wide array of semiconductor chips including but not limited to Microprocessors, field programmable gate arrays or FPGAs as they are popularly known as and many others. An ATE PCB however is designed to test a particular kind of chip set. Visit the link to know about Technotronix’s PCB Functional Testing Services.

Setting up of an ATE PCB Assembly

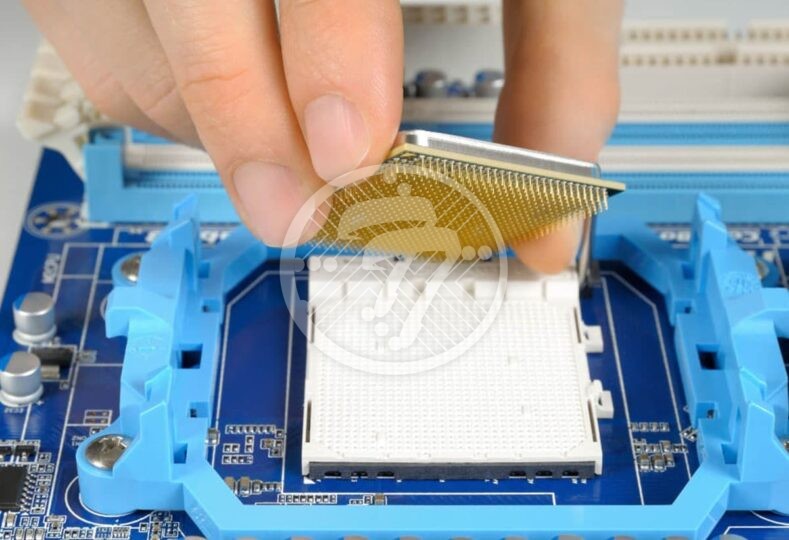

The setting up of an ATE PCB assembly requires superior technical know how as any hitch in the assembly can lead to lost time to market and therefore can have huge monetary repercussions. Since ATE PCBs differ from regular PCBs, ATE PCB managers must be well equipped with all the information regarding them. What they should also know is all the diagrams and illustrations that are associated with ATE PCBs. Additionally they must have thorough knowledge of the hardware as well as the PCB assembly process. Other than manpower equipped with technical knowledge, what is of essence is also an accurate ATE PCB pick and place system. What is also required is proper thermal profiling as also a solder sample, stencil design as well as an aqueous cleaning process. The ATE PCB pick and place system needs to be capable of handling large footprint boards. In addition the advanced versions also have features such as fine pitch repeatability and a large reflow oven. Another differentiating feature of an ATE PCB pick and place machine is selective soldering that ensures that through-hole components are perfectly soldered.

Thermal Profile

Every ATE PCB has a unique thermal profile. ATE PCBs are also known for their number of layers. While a network PCB has up to 20 layers, in case of an ATE PCB the number of layers could be as much as 60. On account of a number of power and ground planes, an ATE PCB also needs a large amount of heat in the reflow process.

The board therefore needs a specific thermal profile, which is characterized by high temperatures compared to a regular PCB. The temperature needs to be such that it heats up the board and yet does not damage the components. The first three zones are set at a higher temperature on account of the ATE PCB’s thickness. This in turn leads to a high ramp rate. Similarly, since it takes time for the paste to melt, the soak times are also different compared to a regular PCB.

Solder Sample

In order to arrive at the right thermal profile, a solder sample from the OEM is a must have. While in a regular PCB a profile can be created using the process engineer’s experience, however in case of ATE boards since no risk can be taken, a perfect thermal profile is created using the solder sample. Only when the perfect thermal profile is created, is the live product run through it.

Stencil Design

Another necessary step that ensures that the solder paste is dispensed properly is a stencil design. Stencil apertures impact solder reflow behavior and are therefore if not used correctly, they can adversely impact the assembly process. Tombstone and bridging is often the result of an inaccurate stencil design that can lead to a whole lot of costly re-work. In turn this causes delays in shipping, increased cost, increased time-to-market, not to mention the stress on the other components of the board.

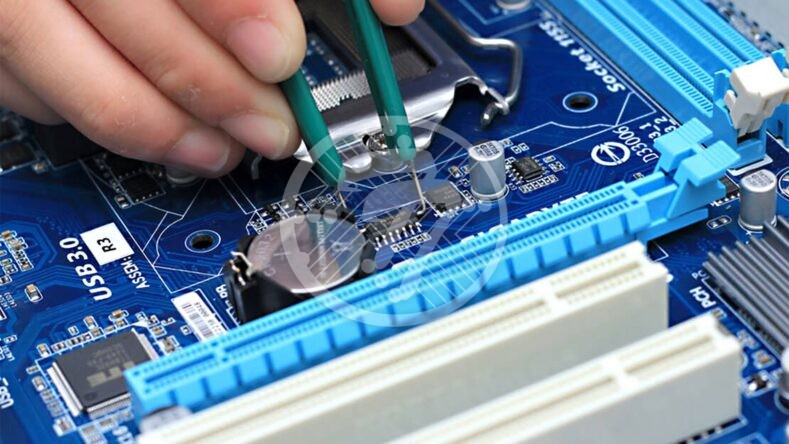

DUT

An important aspect of ATE PCB is its device-under-test site. Any compromise on the part of the DUT can result in the ATE PCB being compromised. For example, if the nuts that are used to keep the DUT socket in place are not properly installed, the DUT socket will not be correctly installed and testing will not be possible. Also DUT pads are sensitive to any contamination. It is therefore important to use solder less pins.

Cleaning

Proper cleaning of the ATE PCBs is a significant requirement as any residue can impact the speed of the board. Any foreign particles or even a fingerprint can jeopardize the efficiency of the board. What is required, therefore, is aqueous cleaning so that all the residue is cleaned from the board using special chemicals.

While ATE PCB assembly is a trusted interface, what it needs is a high degree of maintenance for it to operate at its optimum level and offer the degree of accuracy required.

TechnoTronix is a leading manufacturer of high quality ATE PCB assembly service to electronics manufacturers. Our qualified team of professionals uses the modular approach for PCB Assembly and Layout to simplify the complexity for the Internet of Things Applications. Check out our PCB assembly services! Also, you can drop an email to [email protected] or give us a call at 714/630-9200 to solve your queries or to get a quote.