FUNDAMENTAL TRANSFORMATION IN EMBEDDED ARCHITECTURE

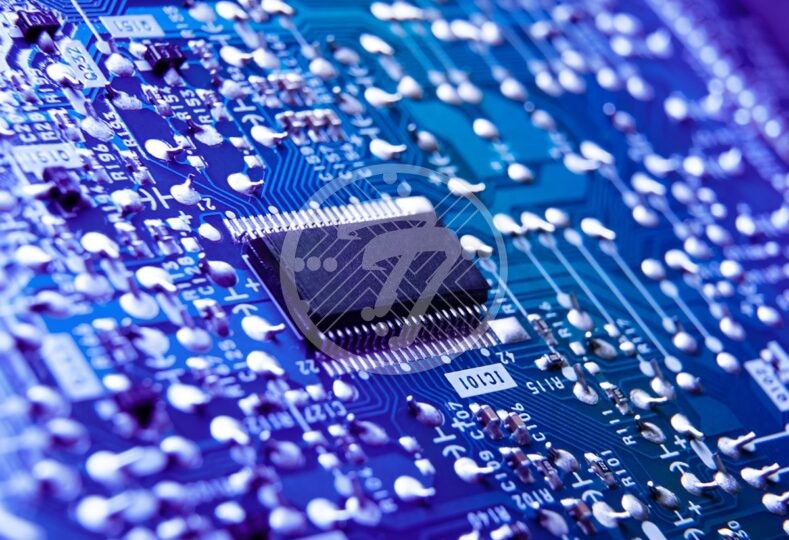

In day to day life, our needs become more dominant on embedded systems; mainly the emphasis is on digital technology that is embedded in most of the hardware and software systems. This has its application not only in automotive control, railways, aircraft, aerospace and Medical PCB Prototype, but also in communications, mobile devices and household appliances.

Dose of Embedded PCB applications:

All of these have wide-ranging effects on society, including security and privacy with modes of working and lifestyle of people. More than 80% of processors used today are in embedded systems. The enhancement in wired and wireless broadband connectivity empowered the growth of numerous intelligent embedded systems.

Health care sector shows a great transformation with using embedded system in small to large devices like X-ray , computed tomography, magnetic resonance imaging, ultrasound imaging, remote monitoring solutions, other fitness devices like Cardiovascular machine with easy navigation, virtual environments and many more.

Other technologies with embedded systems are backplane technology with RF and microwave backplane speed. This shows that the embedded system has its approach in every electronic field where the technology up-gradation is vital.

As electronic and computing technologies have moved forward since the transformation of the era, all the new and existing concepts are implementing the embedded systems to get a feature rich product with reduced power consumption, increasing reliability and cost of operations.

Demands following the transformations:

New up gradations in the areas of imaging, compression and multimedia, demand higher bandwidth, Enhanced Processing Capabilities, quicker response times and more efficient algorithms. The major requirement is for the processors with multiple integrated cores that would improve the throughput of the application.

The embedded systems used in today’s generation demand durability with high estimated life, as there are significant transformations in every sector of the world economy. For instance, the wires, cables and coaxial connectors are now transforming into wireless technologies.

Influencing dominance of embedded PCB systems:

The best part of installing an intelligent embedded system is, it needs less investment for installation and maintenance mechanism. Also the software’s can be easily upgraded or replaced without disturbing the functionalities of the system.

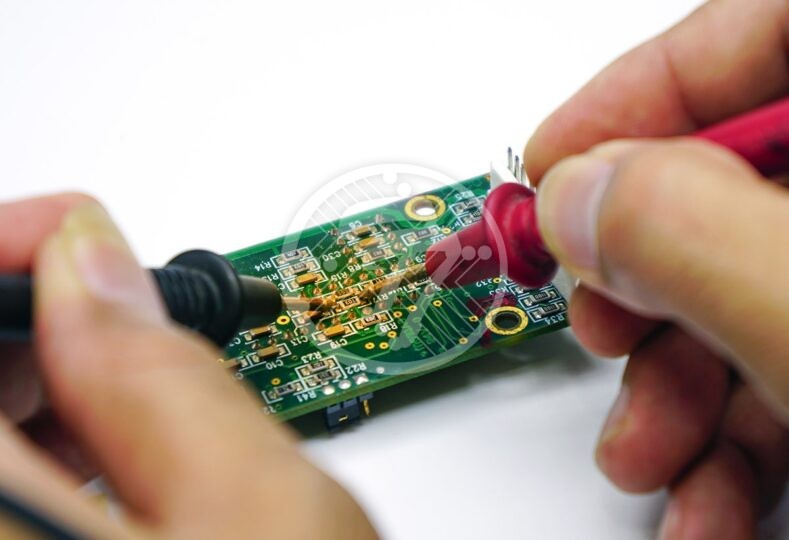

An enhanced model driven approach is applied in the embedded systems to focus on unique design architecture that can suppress the complexities and appreciate the speed level of the systems. This type of approach focuses on Making a layout of an embedded system that can come up with the optimal solutions for challenges like complexities in the system due to integration of numerous features, lot of resources used to amend its performance execution, up gradations to be done in regular intervals of time and quality of services and rework needed for maintenance of the system.

Thus, one of the biggest challenges posed to the embedded engineers is to be well updated with the upcoming technology trends. The more and more new concepts and innovations introduced in the markets, forecasts the product based on an embedded architecture will be better positioned in coming years with optimal investments to derive a state-of-the-art solution.

At Technotronix, we are fully equipped to handle your Embedded PCB manufacturing requirements. With over 4 decades of experience in PCB manufacturing as well as assembling PCBs with differing levels of complexities, we follow industry best practices to ensure we deliver cutting-edge products. Our team of experts and state-of-the-art equipment ensures that all our PCBs meet the industry standards of quality and testing. It is our vast portfolio of satisfied clients that stand as the biggest testimony to our success. In case if you have any questions, please feel free to contact us via email at [email protected]