The Significance of High-Performance Smartphone PCB Manufacturing and Assembly

Modern smartphones are amazing feats of engineering, packing many advanced parts into slim, small designs. At the core of these devices is the Printed Circuit Board (PCB), which connects and supports all electronic components. High-performance printed circuit board manufacturing and assembly are crucial because they directly affect how well the smartphone works, how reliable it is, and its overall performance. This article discusses why high-quality PCB board manufacturing and assembly are so important in the smartphone industry, focusing on key factors and new advancements that drive this vital process.

What is the importance of high-performance PCB assemblies in the smartphone industry?

The Role of PCBs in Smartphones

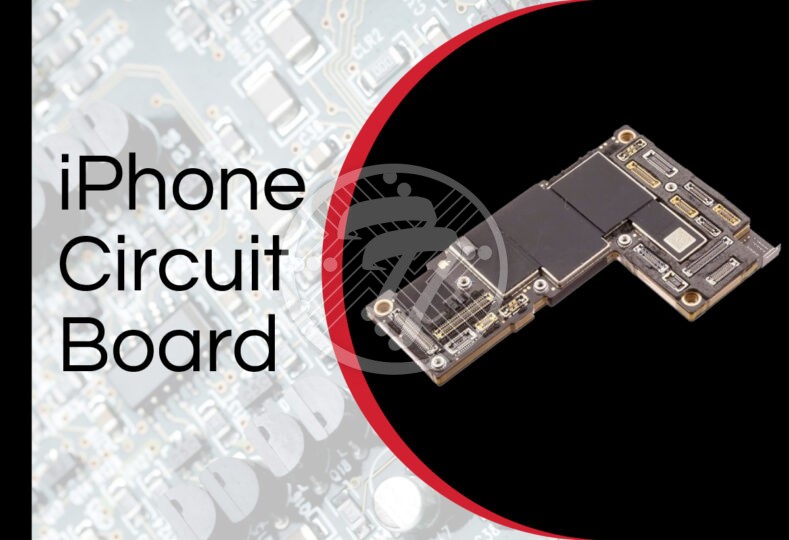

PCBs serve as the backbone of smartphones, providing a foundation on which all other components are mounted and interconnected. These include processors, memory chips, sensors, antennas, and various other integrated circuits. The design and quality of the PCB are paramount in ensuring that these components function harmoniously, delivering the desired performance and user experience.

High-Density Interconnect (HDI) Technology

High-Density Interconnect (HDI) technology is a crucial aspect of high-performance smartphone PCB manufacturing. HDI PCBs are characterized by their higher wiring density per unit area, achieved through finer lines and spaces, smaller vias, and more intricate routing. This technology enables the integration of more components within a limited space, supporting the trend towards thinner and more powerful smartphones.

HDI PCBs also improve signal integrity and reduce signal loss, which is vital for the seamless operation of high-speed data processing and communication functions in modern smartphones. The ability to incorporate multiple layers of interconnections in HDI PCBs allows for enhanced performance and functionality, meeting the ever-increasing demands of smartphone users.

Advanced materials for enhanced performance

The choice of materials in PCB manufacturing significantly impacts the performance and reliability of smartphones. High-performance materials such as polyimide, ceramic, and metal core substrates are increasingly being used in smartphone PCBs. These materials offer superior thermal management, flexibility, and durability compared to traditional FR-4 substrates.

Effective thermal management is particularly critical in smartphones, where densely packed components generate significant heat. Advanced materials help dissipate heat more efficiently, preventing overheating and ensuring the longevity and reliability of the device. Moreover, these materials can withstand the mechanical stresses associated with daily use, enhancing the overall durability of the smartphone.

Miniaturization and Component Integration

The trend towards miniaturization in smartphone design demands equally innovative PCB manufacturing techniques. Miniaturization involves reducing the size of individual components and integrating them more closely on the PCB. Techniques such as embedding passive components directly into the PCB substrate and using System-in-Package (SiP) technology are gaining traction.

Embedded components reduce the overall footprint and improve electrical performance by minimizing the distance that signals need to travel. SiP technology, which integrates multiple ICs into a single package, further enhances compactness and functionality. These advancements enable manufacturers to pack more features and capabilities into smaller, more efficient devices, meeting consumer expectations for slim and lightweight smartphones.

Precision Manufacturing and Assembly Techniques

Precision in manufacturing and assembly is vital to produce high-performance smartphone PCBs. Advanced manufacturing techniques such as laser drilling, precision etching, and automated optical inspection (AOI) ensure the accuracy and consistency of PCB production. These techniques allow for the creation of fine lines and spaces, crucial for the dense component placement required in modern smartphones.

Automated assembly processes, including surface mount technology (SMT) and robotic soldering, further enhance the precision and efficiency of PCB assembly. These automated systems reduce the likelihood of human error, ensuring that each component is placed and soldered correctly. This level of precision is essential for maintaining the performance and reliability of high-performance smartphones.

Enhanced Surface Finishes

Surface finishes play a significant role in the performance and reliability of smartphone PCBs. High-quality finishes such as immersion gold, immersion silver, and organic solderability preservative (OSP) provide better protection against oxidation, improve solderability, and enhance the durability of the PCB.

Immersion gold, for example, offers excellent surface planarity and long-term reliability, making it ideal for high-frequency applications. These advanced finishes ensure that the electrical connections between components are stable and reliable, which is crucial for the overall performance of the smartphone.

The Impact of 5G Technology

The rollout of 5G technology has a profound impact on smartphone PCB manufacturing and assembly. 5G networks operate at higher frequencies and require faster data processing capabilities, necessitating significant advancements in PCB design and materials. High-frequency PCBs need to minimize signal loss and maintain signal integrity, which requires precise manufacturing techniques and the use of low-loss materials.

The increased power and thermal loads associated with 5G applications also demand advanced thermal management solutions. This includes the integration of heat sinks, thermal vias, and metal core substrates to effectively dissipate heat. Meeting these stringent requirements is essential for ensuring the performance and reliability of 5G-enabled smartphones.

Sustainability in PCB Manufacturing

Sustainability is becoming an increasingly important consideration in PCB manufacturing. The smartphone industry is under pressure to reduce its environmental footprint by adopting eco-friendly materials and processes. This includes the use of lead-free solder, recyclable materials, and energy-efficient manufacturing techniques.

Additionally, there is a growing emphasis on waste reduction and recycling within the production process. Sustainable practices not only benefit the environment but also enhance the brand image and appeal of smartphone manufacturers, who are increasingly expected to demonstrate corporate social responsibility.

Advanced Testing and Quality Assurance

Ensuring the quality and reliability of smartphone PCBs is paramount, given the critical role they play in device functionality. Advanced testing and inspection techniques are essential for identifying defects and inconsistencies early in the production process. Techniques such as automated optical inspection (AOI), X-ray inspection, and functional testing are becoming more sophisticated and widely adopted.

These methods allow manufacturers to detect and address potential issues before the PCBs are assembled into final products. By maintaining stringent quality assurance protocols, manufacturers can ensure that their PCBs meet the high standards required for modern smartphones, reducing the risk of failures and enhancing customer satisfaction.

The Role of Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are playing an increasingly significant role in PCB manufacturing and assembly. AI can assist in optimizing PCB designs by predicting potential issues and suggesting improvements. Machine learning algorithms can analyze vast amounts of production data to identify patterns and optimize manufacturing parameters.

These technologies enhance the efficiency and accuracy of the manufacturing process, reducing the likelihood of defects and improving overall product quality. By leveraging AI and ML, manufacturers can stay ahead of the competition and meet the growing demands of the smartphone market.

Customization and On-Demand Manufacturing

The ability to produce customized PCBs on-demand is becoming increasingly important in the smartphone industry. Advances in digital manufacturing technologies allow for greater flexibility and responsiveness to customer needs. On-demand manufacturing reduces lead times and allows us to produce small batches, catering to specific requirements and reducing inventory costs.

Customization enables smartphone manufacturers to differentiate their products and meet the diverse needs of their customers. By offering tailored solutions, manufacturers can enhance customer satisfaction and loyalty, gaining a competitive edge in the market.

Future Trends and Innovations

The future of high-performance smartphone circuit board manufacturing and assembly is set to be shaped by several emerging trends and innovations. These include the continued development of flexible and foldable PCBs, the integration of advanced sensors and biometric technologies, and the use of more sophisticated AI and ML algorithms in design and production.

Flexible and foldable PCBs will enable the creation of new form factors and functionalities, while advanced sensors and biometric technologies will enhance the capabilities of smartphones. AI and ML will further optimize the manufacturing process, driving efficiency and innovation.

By staying at the forefront of these trends, PCB manufacturers can continue to push the boundaries of what is possible, delivering cutting-edge solutions that meet the evolving needs of the smartphone industry.

Conclusion

The significance of high-performance smartphone printed circuit board manufacturing and assembly cannot be overstated. As the foundation of modern smartphones, PCBs play a critical role in determining the functionality, reliability, and overall performance of the device. Advances in HDI technology, materials, miniaturization, precision manufacturing, and testing are driving the industry forward, enabling the creation of more powerful, efficient, and compact devices.

The impact of 5G technology, sustainability initiatives, and the integration of AI and ML are further shaping the future of PCB board manufacturing. By embracing these advancements and staying ahead of emerging trends, Technotronix ensures that their PCBs meet the high standards required for today’s smartphones, delivering superior performance and customer satisfaction.

With over 4 decades of experience in PCB manufacturing as well as assembling PCBs with differing levels of complexities, we follow industry best practices to ensure we deliver cutting-edge products. Our team of experts and state-of-the-art equipment ensures that all our PCBs meet the industry standards of quality and testing. It is our vast portfolio of satisfied clients that stand as the biggest testimony to our success. In case you have any questions, please feel free to contact us via email at [email protected].