PCB manufacturing and PCB assembly being a lead to new innovations in the Transportation industry

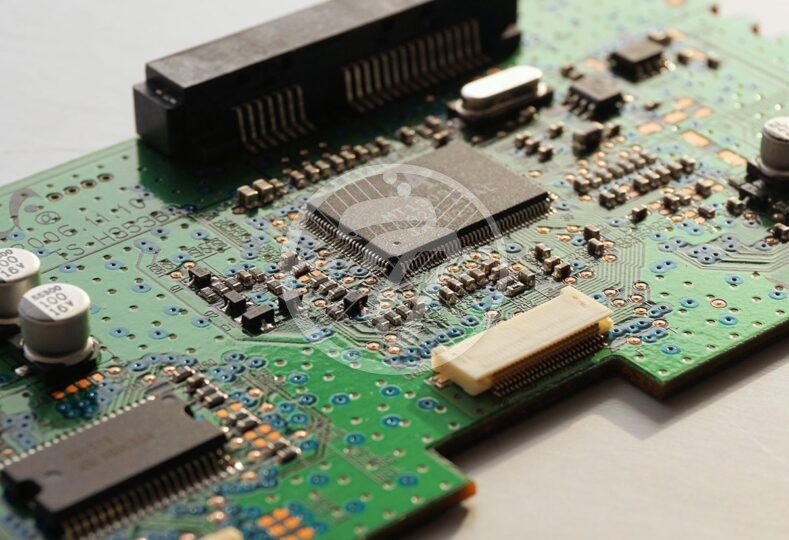

The transportation industry has come up with many effective innovations in providing electronic solutions that dwells on the use of complex high customized PCB’s. For risk free transportation solutions, the printed circuit board industry has developed proven tech PCB Layout to serve the technological advancement in road transport, rail, aerospace, shipping, marine and automotive markets. This has also posed a challenge among the PCB manufacturers to offer high end customization right from the material selection, different shape and sizes by providing contract manufacturing, consigned or complete turnkey solutions as per the demand of varied customers across the globe. With this different state of the art techniques like SMT (Surface Mount Technique), Through Hole Techniques are highly in use for smooth PCB fabrication and PCB assembly. The increased use of circuit boards is seen in the transportation industry with modified navigation systems, tracking systems, alarm systems, lightings and many other user friendly devices and electric systems installed in cars, trucks, coaches, ships, submarines, trains, aircrafts, helicopters, buses and many more vehicles. These types of application demand for standard and multi-layered PCB with lower pitch BGA and with varied type of dielectric. Apart from this rigid/flex PCB is also used by many OEM’s and EMS in the transportation sector. This article brings to light many technological advancements in the transportation industry, the PCB used in its application and challenges faced by the PCB manufacturers and tech designers.

With the global dynamic discoveries and innovations featured in the transportation sector, the printed circuit boards with high speed and complex layout requires a high energy delivery system with better thermal profiling for any type of design tool be it schematic capture, layout or simulation pcb layout method. Apart from this, a system aware engineering with 3D modulations are used for tracing the system mechanism operating in the circuit board to optimize the performance. The Multi layered, Single/Double sided and Box Build PCB assembly is being used specially for the advancement in devices used in the transportation industry.

The challenge faced by the PCB designers is to present a tech savvy compact design with multi functionality features that is capable of extra memory, power potentiality and processor with modified data management systems. The PCB’s to be manufactured with captivating costs is also a tough job for PCB designers, especially for serving the automotive electrical solutions. The technology is now getting rid of these challenges with the use of rigid/ flex PCB that has flexible molding and ultra HDI features which well suits the requirements of the transportation industry.

PCB Manufacturing Innovation in Transportation Technologies:

- The GPS tracking device has shown new innovations in its usage to track the vehicles by installing it with the battery of vehicles that directly transmits the vehicle position to the web server. The Rigid/ flex PCB are high in use with the increased use of mini GPS tracker used in various transport systems.

- The reversing alarms are used in trucks, fork trucks, electric vehicles, coaches, buses, tankers and other heavy vehicles. Another type of alarm system includes the talking alarm which has a risk free warning system that talks about the exact dangers like non application of a hand-brake, seatbelt unfastened, fuel required etc. Other car alarms and immobilizers used for vehicle security for locking the doors and steering wheel are also high in use. For these automotive systems, burglar alarm circuit and car alarm circuit are high in use in the PCB market.

- The auto-transformer rail controllers are also showing its innovations in controlling the railway systems that have railway signaling electronics and detection devices that are used for train control mechanics. Nowadays, train lighting systems have smooth operating models with rail traffic light controllers and LED lightings used in trains.

- The cars and heavy duty vehicles now have an installed system performance sensor that controls the braking systems, torque sensors, accelerometer and other automotive component sensors.

- The double sided PTH PCB’s, HDI layer PCB and multi layered PCB are used in the in train communication tracking are highly in use for communication systems used in the railway industry.

- The Manglev trains without wheels that runs with magnetic tracks will slowly replace the traditional rail system with developments in electronic devices.

- Driverless cars and electric cars with calibrated robots and navigation systems add to the recent innovations.

- A smart road system used to understand the traffic patterns with noting the tires hitting the ground that guides the driver to read the traffic and route the destination.

- Other innovations are found in metros, subway trains, ship, submarines, the speedboats, Paragliding systems, ergonomic transport systems used in the medical industry, electric trucks etc.

These innovations in transportation industry poses demand for the PCB fab and PCB prototyping services that has high end customization in its production process, high grade quality, on time delivery of orders, effective supply chain and vendor management. It has also become a mandatory aspect to have a PCB fabrication and assembly as per the international standards of quality.

At Technotronix, we are fully equipped to handle your PCB manufacturing requirements. With over 4 decades of experience in PCB manufacturing as well as assembling PCBs with differing levels of complexities, we follow industry best practices to ensure we deliver cutting-edge products. Our team of experts and state-of-the-art equipment ensures that all our PCBs meet the industry standards of quality and testing. It is our vast portfolio of satisfied clients that stand as the biggest testimony to our success. In case if you have any questions, please feel free to contact us via email at [email protected]