Electronics New Product Introduction (NPI) Prototypes in EMS – A Checklist to achieve zero defects for OEMs!

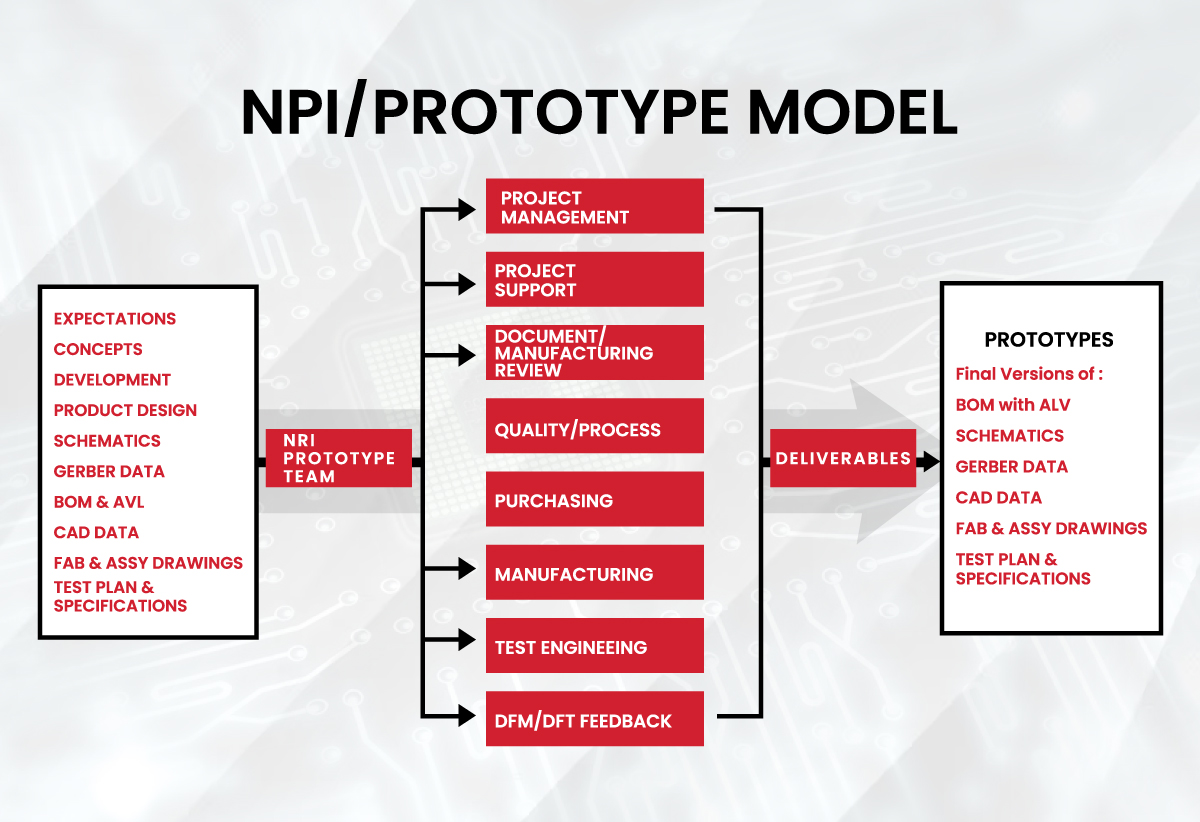

OEMs are innovating new product ideas regularly to stay ahead in the electronics market. To successfully convert a product idea from a preliminary prototype into a final product, you require a robust New Product Introduction (NPI) process. As an OEM, you can build reproducible and cost-effective products with strategic planning of time and resources. A well-established NPI process enables you to transform a working prototype design into a marketable end product. It can be a new product altogether or a refinement of an existing device. But exhaustive research on the customer requirements is recommended before proceeding with the NPI process.

Generally, a prototype includes temporary circuits or supplementary components to establish the proof of concept. They become redundant in the final product design. A detailed BoM analysis is mandatory to ensure that the components are in the PROD phase of their lifecycle. Procuring the parts in bulk, tracking their lead time, and avoiding counterfeit components are all critical tasks while preparing for your final product manufacturing. If you are working with an experienced EMS partner from the initial design stage itself, they can assist you in fine-tuning your prototype design to build a faultless and economical product.

Most OEMs implement an NPI process for the advantages it brings like enhanced product quality, reduced manufacturing cost, faster time to market, better customer satisfaction, etc. Yet, there are possibilities that your product launch may fail due to delays in the schedule, unrealistic estimation of the product demand, inappropriate product pricing, or budget overruns.

To overcome such instances, it is necessary to outline every task involved in the NPI process, along with the corresponding stakeholders and the expected timelines.

What is the electronics NPI prototype checklist and why is it required?

The NPI checklist is a comprehensive list of all the tasks involved in electronics product design, testing, and manufacturing from the prototype phase to mass production. The checklist allows you to monitor the product development process and identifies the root cause for delayed timelines or missed verifications. It establishes a collective understanding of the expected quality by defining the scope and requirements of the project. Each material specification, inspection method, testing procedure, and manufacturing process is documented and tracked. Following your prototype checklist can reduce design iterations and improve PCB manufacturability. It can be used as a reference for future product builds and improves the overall efficiency of your NPI process.

What does an electronics NPI checklist include?

The key purpose of an NPI checklist is to identify the current project status, outline the roles and responsibilities of the team members, set goals for quality, budget, resources, etc. and establish a support structure. You need to check if your product is addressing the customer’s requirements. Assigning stakeholders for each task avoids duplication of the work and improves accountability. If you set, clear goals on expected quality and allocated budget then your product launch will be on time. Adhering to a standard documentation process will be beneficial for scaling your production capacity.

A typical NPI checklist covers all the milestones of a product development cycle. You can add more headings based on project type, but a typical NPI checklist includes:

- First thing on the NPI checklist is to mention your project name. Add your company nomenclature and numbering if required.

- Specify the start date and expected end date for electronics project design and manufacturing indicators. A target end date helps you to measure the delay in the project.

- Include the project description and scope in detail. Here the product features and specifications are also stated. The chosen manufacturing process and details like component types used, PCB assembly method required, testing procedures, etc are all included.

- Start with design milestones like the schematic release, netlist generation, layout completion, and Gerber file release. The design team has to publish associated documents like product architecture, bill of materials, approved vendor lists, test procedures, result report formats, etc.

- Track your supply chain closely by listing all the components, materials, and subassemblies used in the product design. The procurement team has to identify the BoM components’ lead time and plan their sourcing accordingly.

- The fabrication, assembly, and testing process have to be tracked and the expected timeline has to be displayed in the NPI checklist. This may include drawing release date, fabrication completion timelines, shipment sampling date, etc. Each unit test report has to be archived along with a rework description.

Usually, the EMS partners ask their customers for the target launch date and the cost budget details. They understand the product application and the certifications required. In the first round, EMS partners check for manufacturability and provide DFM reports to the OEMs. They clarify all engineering issues and run a first trial production. In the second iteration, they will finalize the production line and assess reliability. Further, they work on process optimization and higher production yield.

Tips to avert NPI launch failures:

Though the checklist is designed to ensure a successful NPI launch, there are some reasons for failures like schedule delays, cost overruns, resource shortages, poor product quality, etc. Since it is a cross-functional process, the stakeholder’s capabilities and communication skills are crucial. The following tips can save your next product launch from failure.

- Pause and review your existing NPI process for any skill gaps or process inconsistencies to identify the root cause.

- Work with all stakeholders to analyze the risk involved in technology, project schedule, and finance.

- Create a base plan and discuss the next steps to be taken with measurable goals. Assign task owners for each line item to avoid execution delays.

- Ensure operational readiness by training the staff for NPI launch excellence.

- Check for resource shortages and reassign if required.

- Check for work instructions and process standards to deliver quality products.

- Hire a competent project manager to prevent cost overrun. Detailed project planning and follow-up are important to keep the expenses under control.

Conclusion:

To achieve product launch excellence, a robust electronics NPI process is mandatory. A thorough NPI checklist can assist you to build zero-defect electronics products. Pick an experienced EMS partner and collaborate from the initial design stage to launch your next product successfully in the market.

We provide PCB prototyping services with a unique way of using advanced techniques like automated layout analysis, algorithms, and custom technical specimens depending on the Gerber file and BOM (Bill of Materials) required for a particular prototype. We assure you to deliver high-quality custom prototyping and NPI services with the multi-layered quick-turn prototype, chips, testing, and others. Our focus is to fulfil every requirement of multiple industries like Defense, medical, aerospace, electronics, renewable energy, telecommunication and more.

From initial design, development, prototype to full scale production and after-market support, we provide you a complete package of industrial electronics manufacturing. To get more information about NPI implementation, request a quote or reach us at [email protected] or at 714/630-9207.