How and Why the utilization of SMT stencils simplify the Process of PCB Prototyping?

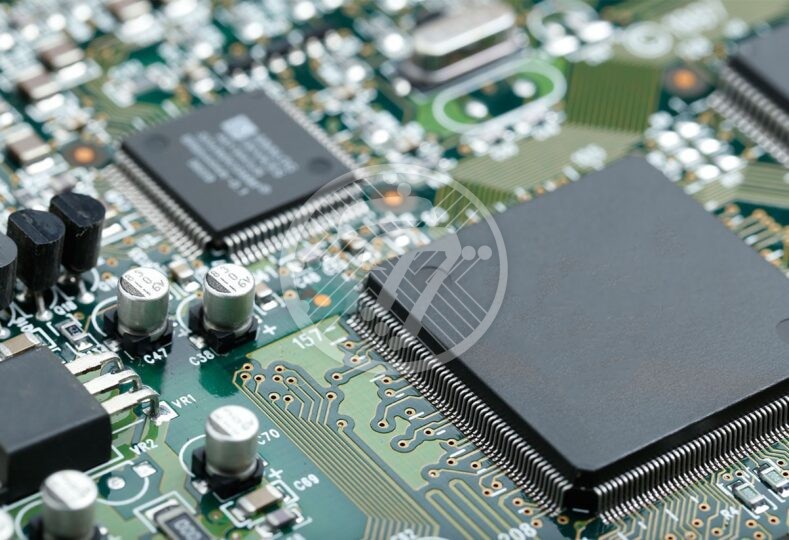

The process of creating a PCB is complex and involves a large number of steps beginning with the Layout stage and culminating in the assembly of the boards. The entire process goes through specifications, electrical design, physical design, manufacturing and finally, assembly. Most of these stages are replete with chances of probable error.

The printed circuit board assembly process alone comprises of the following stages- a) applying solder paste b) pick and place components c) heat/reflow solder d) cool and test.

The use of laser cut SMT stencils in the process of applying solder paste cannot be over emphasized. Solder paste only needs to go where the component must be in contact with a metal landing pad. This is made possible with a solder stencil. With the solder screen in correct position, a runner is moved across the screen applying solder paste through the holes, onto the board.

Essentially a stencil works in the following manner:

- First and foremost, a stainless steel laser is employed so that openings are cut out for each component that will be on the board.

- The stencil is thereafter aligned on the board.

- Solder paste is applied all over the stencil.

- Once the stainless steel foil is removed, the solder paste is ready for placement of the components.

Benefits of using a PCB stencil

Laser cut SMT stencils have smooth internal pad walls, which facilitate superior paste release. Its advantage also stems from the fact that it is fast and easy to work with and allows for a high degree of accuracy. Since these stencils significantly reduce the potential for errors, there is little risk of having to rework the board or replace its components. With the time and labour required to manufacture the board significantly reduced, what also results is a significant cost advantage. The fact that the stencil makes it possible to print fine print devices is also an added benefit. Stencils therefore go a long way in increasing the overall quality of the PCB since the chances of bridging, tombstoning or balling on the board are significantly reduced.

Prototype Stencils are particularly of use where:

- The number of surface mount components are high

- The component placement is finalized

- Easier soldering

Types of SMT stencils available

There are a number of different types of stencils that can be opted for during the electronics assembly process. Some of them include:

- Desktop Stencil- This is particularly chosen in case of hand assembly of prototypes as it makes application of the solder paste by hand, easy.

- Framed Stencil- These in turn can be categorized as either fixed frame or universal frame stencils. The fixed frame stencil, as its name implies has the stencil fixed to the frame. In case of a universal frame stencil on the other hand, the stencil is held within a frame. This kind of stencil allows for a reduction in cost as they allow for changes to the unit.

- Rework Stencil- A frameless stencil, it allows for reloading of components and thus comes in very handy in cases where a certain problem component needs to be tackled.

Typically stencils are made out of stainless steel on account of their durability, however, stencils made up of Mylar are also common. Varying from .005″ to .007″ in thickness, a large majority of stencils are found in 20″x20″ size.

Buying a custom stencil from a reputed manufacturer offers the following advantages:

- It allows for accuracy

- They are delivered in a timely manner

- Reorders are easy to make

- They are affordable- In fact it takes only a handful of parts before the stencil starts to pay for itself in terms of accuracy, time saved and of course increased yield.

- They are compact and easy to handle

Technotronix is one of the kingpins in offering PCB Layout and manufacturing solution to all predominant industries. With a strong team of technical professionals, it has gained expertise in providing faster and cost effective PCB Prototyping Services.

We provide professional PCB Assembly services with 40 years of expertise. Our accurate PCB assembly process meets the quality standards, including ISO-9001:2015, RoHS, and more. You can rely on our PCB design tools that, in turn, lead to that perfect PCB Assembly. Our superior engineering capabilities mean that each board matches your exact requirements and technical specifications. If you have any questions or any requirements related to PCB assembly service, please feel free to contact us via email at [email protected] or call at 714/630-9200.