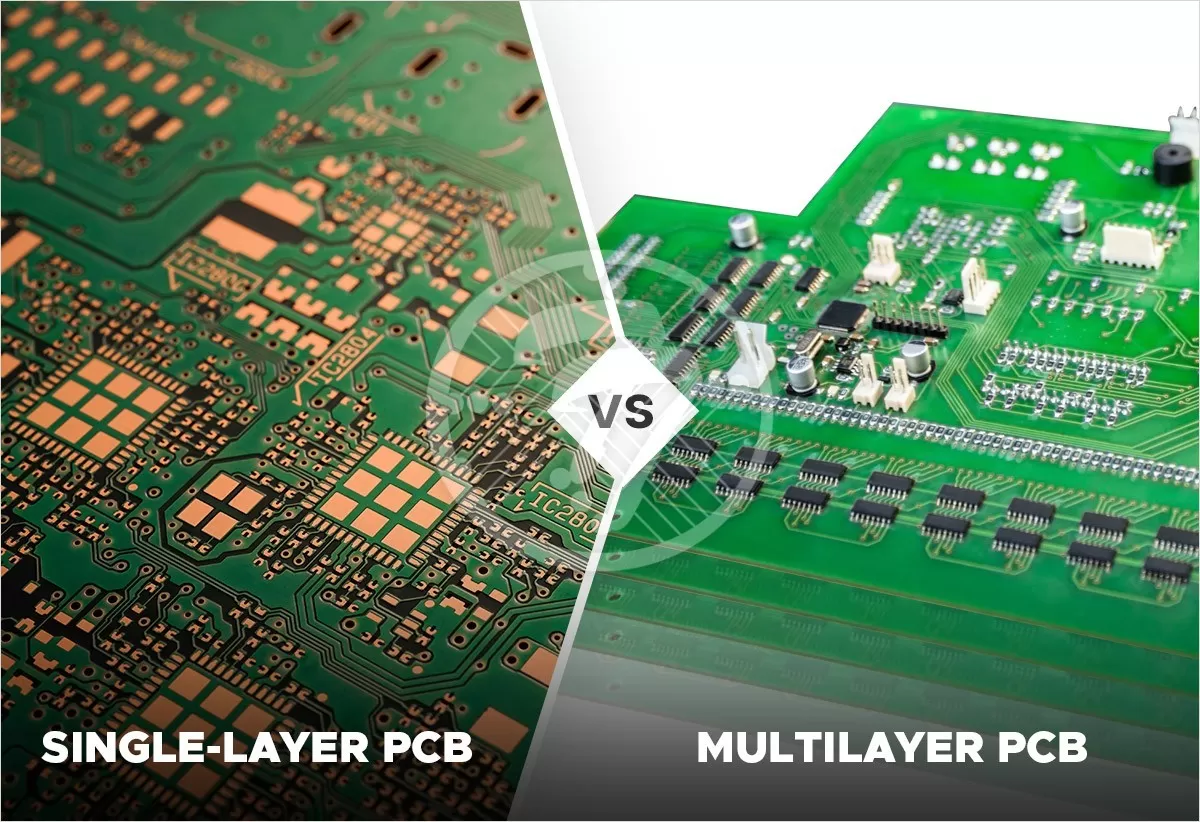

When it comes to choosing the right custom PCB boards for your project the one question that you need to deal with at the outset includes whether to go for a single-layer or multilayer printed circuit boards. How do you decide whether your project require single-layer or multilayer printed circuit boards? To be able to answer this question, it is important to get into a detailed understanding of both.

Single-layer or single sided PCBs

A single-sided board, as its name suggests has the components on one side of the board and the conductor pattern on the other. Typically, such boards are used for simpler devices.

Single-Layer PCB Advantages

The many advantages that single-layer printed circuit boards offer, include:

- Low Cost

The simpler nature of these boards translates into the fact that they need fewer resources, less time as also lesser expertise to design as well as fabricate the boards. All of this translates into low costs of single-sided boards rendering your project, efficient.

- Easy to design and produce

Because of their simplicity, it is easy to design these boards as also for manufacturers to produce them without any issues. Additionally, it is easy for manufacturers to cater to high volumes. In fact, with rising quantities, the price of the board will be even lower, making the boards even more efficient.

- Quick turnaround times

Once again the simplicity of the boards lend themselves to quick turnaround times even at high volumes. This can prove to be a significant source of competitive advantage as your go-to-market plan can be expedited.

Despite the many advantages that they offer, single-layer PCBs also run into several limitations, important among them being:

- Limitations of design

While the simplicity of their design is an advantage in several terms, it can also turn out to be their limitation. For complex devices where there are many components, the space offered by a single-layer printed circuit board does not prove to be enough.

- Power and Speed

With limited number of connections, the power and speed of the board is significantly impacted. This makes single-sided PCBs not too usable when it comes to complex devices where power and speed is of essence.

Single-Layer PCB Applications

Because of their low cost and ease of production, single-layer PCBs find a place in several devices were storing of a large amount of data is not a prerequisite. Some of the devices where single-layer PCBs find wide-spread application include:

- Radios

- Printers

- LED lights

- Calculators

- Coffee makers

- Sensors, and more

Multilayer Printed Circuit Boards

Multilayer PCBs are made up of three or more double-sided boards stacked together. With multiple conductors patterns the area available for wiring significantly increases. Typically, an even number of layers are preferred as odd number of layers can lead to issues such as warping and twisting once the soldering process is done.

Multilayer PCB Advantages

The many advantages that multilayer PCBs offer, include:

- Useful for complex designs

Complex devices that have a high number of components and circuits benefit from the use of multilayer PCB. Devices with several uses as well as advanced capabilities need this kind of complexity. With the miniaturization of devices becoming a growing trend, the use cases of multilayered PCBs are only rising. Many of the multilayered boards also come with features such as impedance control and electromagnetic interference shielding, further improving the quality of the board and of the device.

- High on Power

Because of their high circuit density, the boards are also more powerful. What this means is that they offer high operating capacity as well as speed, making them especially useful for advanced devices.

- Highly Durable

With an increased number of layers, the thicker board is also more durable. It is far more capable, therefore, of withstanding harsher conditions.

- Size

Small size and lightweight are added features of a multilayer board. This makes them ideal for the miniaturization of devices.

- Single connection point

The fact that they work with a single connection point is an added advantage in terms of simplicity of design and weight.

Also checkout : Advantages of Multilayer PCB in Electronic Industry

Limitations of Multilayer PCBs

Despite the many advantages that multilayer boards offer, the limitations that they present include:

- Increased manufacturing costs

As opposed to single-layer PCBs they come with a higher manufacturing cost.

- Potentially longer manufacturing time

Because of the complexity of design and high component density, typically they come with a longer Manufacturing time.

- More complex repairs

In terms of repairs too, the process is more complex as well as time consuming.

Common applications of Multilayer PCBs include:

- Computer components

- Mobile phones

- GPS devices

- Heart monitors

- X ray equipment

- GPS technology

- Automotive industry

- Aerospace industry

- Military applications, and more.

Single-Layer vs Multilayer PCBs, who wins the ultimate battle?

The answer to that lies in your requirements. It is the project that will determine the type of board that works well. To come to the right conclusion on what kind of board will work well for you, you need to consider the following aspects:

- The level of functionality required- More complex functions require multi layered boards.

- The acceptable size- If your requirement is that of a smaller space, multilayer boards are likely to work better.

- The need for durability- Typically multilayer PCBs are more durable.

- Your budget- If your budgets are low, single-layer PCBs are likely to make a better fit.

- Timelines- Single-layer boards have faster turnaround times.

So go ahead and make the right choice!

At Technotronix, our highly qualified and experienced multilayer PCB manufacturer ensure that all the layers are correctly registered. Adhering to high quality multilayer PCB manufacturing practices, we are equipped to handle complex boards with up to 24 layers, which are laminated to insulate them. Whether it is sticking to the product specifications or stringent quality controls, there is no stone that we leave unturned in our quest to deliver the best.

Get a Quick PCB Fabrication Quote