Top 10 Reasons To Build Lead-Free And RoHS Compliant PCB Assembly

The ROHS directive issued by the European Commission (EC) which came into effect from July 1, 2006 has brought about a significant shift in the PCB Assembly and Fabrication process. ROHS, which is an acronym for Restriction of Hazardous Substances was brought into effect for the purpose of drastically reducing the use of toxic materials in the manufacturing and assembly of electrical and electronic products. The ROHS directive specifically bans electrical and electronic products that contain more than specified levels of any of the six hazardous substances listed below

- Lead

- Mercury

- Cadmium

- Hexavalent Chromium

- Flame retardant PBB

- Flame retardant PBDE

The ROHS Circuit board came into law from July 1, 2006 and empowered EU member states to refuse electronic and electrical products that contained any of the above mentioned hazardous substances in quantities greater than specified.

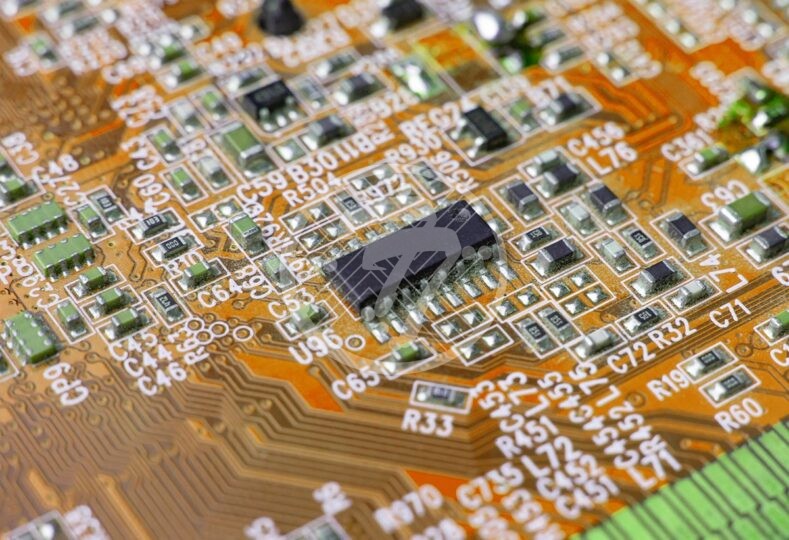

Complying with the ROHS directive required a major shift in the PCB Assembly process. This is primarily because the ROHS directive requires organization involved in the PCB assembly process to ensure that none of the hazardous substances specified in the directive is used in any of the assembly process including board, soldering and component. For instance, organizations providing PCB Assembly services had been using lead based solder for decades, the new directive required them to shift their process to include lead free soldering in the design and assembly of Printed Circuit boards used in the electrical and electronic industry. Also most of the circuit boards manufactured till then were coated with a finish that included lead and tin which also needed to be changed to lead free to ensure compliance with ROHS standards.

It has now become even more imperative for organizations to build a PCB Assembly process that is not only lead free but also ROHS compliant. The reasons range from legislative to environmental as well as financial.

Top 10 reasons for a lead free and ROHS compliant PCB Assembly process:

- If you are a PCB Assembly services provider supplying to the European Union, then you will need to ensure ROHS compliance in your assembly process in order to do business in the EU. This is because any electronic or electrical product entering the EU needs a Bill-of Material that is ROHS compliant as well as use of technology that is ROHS compatible.

- Even if you do not have business in the EU, it is better to plan proactively to build a ROHS compliant, lead free PCB Assembly process since almost all major countries and states are already planning legislation that limit the use of hazardous and environmentally damaging substances in industrial processes.

- The introduction of RoHS has helped reduced environmental waste especially in third world countries which end up being the dumping ground for most electronic waste.

- Health and liability risk associated with working with lead have become a major reason why legislation has been passed restricting the use of lead in many industries. In the PCB assembly process, the health risk posed to workers during contact with solder paste is what has led the move towards lead free PCB Assembly. A lead free PCB assembly environment provides eliminates health risks to workers and reduces liability of organizations involved in the assembly process.

- With the use of lead free soldering, PCB designers have been able to simplify the design of the board itself which is the primary reason for a significant breakthrough in the size of the Printed Circuit boards. Simpler pcb layout has made it possible for PCB manufacturers to assemble and fabricate smaller boards, something which they had been struggling to do before. The ability to assemble smaller printed circuit boards is what has led to the introduction of faster and smaller hand held devices like tablets and cell phones.

- Another big reason for using lead free soldering is that it makes it possible to assemble printed circuit boards with fine, tightly packed pitch components such as those required in the semi-conductor industry.

- A major concern regarding the use of lead free assembly has been the issue of reliability since there is no common standard governing lead free soldering. But these concerns have proved to be unfounded as statistics conclusively show a reduction in errors and customer complaints in the EU region since the introduction of ROHS standards.

- Lead free soldering has made mass assembly of smaller and tighter Printed circuit boards much faster and cheaper than before. This has enabled organizations using ROHS compliant lead free assembly process to achieve significant cost savings.

- In addition, companies using lead free, ROHS compliant PCB assembly process are able to use it as a big selling point while pitching to clients.

- Being lead free and ROHS compliant also increases your ability to compete in a global environment.

TechnoTronix is one of the leading manufacturer of proven PCB layout and PCB assembly service to the electronics manufacturers. Our main strength lies in the extensive experience and skilled team of experts to build Lead-Free and RoHS Compliant PCB Assembly and manufacturing solution. To get more insights into RoHS circuit boards, You can drop an email to [email protected] or give us a call at 714/630-9200 to solve your queries or to get a quote